SCADA systems have grown to help operators monitor oil and gas operations, several different options available to those in the field.

SCADA (supervisory control and data acquisition) has been a key technology in the monitoring of oil and gas operations in onshore, offshore and pipeline operations.

New approaches combining AM/FM-GIS (automated mapping/facilities management) with SCADA are bringing about innovations for field operators and mobile maintenance workers.

The oil and gas industry is also adopting new computer-based technologies from the Internet of Things (IoT) and GIS (geographical information systems).

System interoperability with open communications in automation is critical to enabling new technologies to be integrated into existing SCADA systems. The key is integrating GPS (Global Positioning System) and indoor location services via micro-geolocation in smart and productive ways with SCADA. Companies are finding great value in knowing the precise location of assets and personnel, information from which they can make better decisions.

The open and closed development of SCADA architecture

In the past, SCADA suppliers provided proprietary solutions. During the 1990s — driven by commercially available operating systems such as Microsoft Windows — HMI (human-machine interface), communications and telemetry moved toward open architectures. The OPC Foundation and other industry associations were formed to guide interoperability standards.

Now, many SCADA vendors are moving back toward the proprietary model. This is driven by the reality that the majority of independent SCADA providers have been acquired by equipment vendors, and as a result optimized their software to the control equipment of their parent company. The remaining independent SCADA providers continue to be vendor agnostic, focusing on an open architecture designed for heterogeneous control equipment such as PLCs (programmable logic controllers).

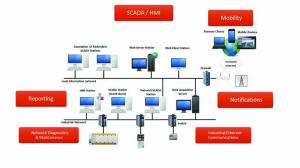

Today, independent vendors provide a wide array of nonproprietary modules, including HMI, real-time database structures, historian software, mobility, trending and alarm management, communication protocols, data analysis and reporting software, and multi-station networking and redundancy. The globally independent SCADA vendors are leading the adoption of the new location-based technologies and are revolutionizing the way SCADA is used.

Micro-geolocation and SCADA on the move

Since the ‘90s, GPS has been used for outdoor navigation using real-time navigation and mapping systems. And the oil and gas industry has incorporated LBS (location-based services) for mobility for over 20 years. The value of LBS is seen in determining the exact location of a person, vehicle or piece of equipment. It’s also key for safety in the case of an emergency to determine the immediate location of personnel. In addition, LBS makes it much easier to locate and conduct the maintenance of a remote pump or RTU (remote terminal unit) or other outside equipment. It has also shown its usefulness to direct personnel to a remote area of a pipeline and/or the safest route to the location when weather, traffic, etc., are a concern.

Indoor location systems, based on PBS (proximity-based services), come into play when satellites are unavailable. They offer more accurate location services than GPS, often called micro-geolocation. This technology allows targeted determination of location while indoors in a refining plant, pipeline or aboard an offshore oil rig.

Micro-geolocation is already used in airports, convention centers and retail, and it offers oil and gas operations some interesting advantages. It is particularly useful when operators, maintenance personnel or technicians are inside a compressor station or a pumping station where GPS signals are not available. It can address safety issues and help track which equipment has been maintained and how often. Lastly, micro-geolocation can help to navigate different floors and levels of a facility to assist in locating the right sensor or a faulty valve on a piece of equipment.

For example, on an offshore rig, GPS may tell you which unit you are located on, but micro-geolocation will tell the operator or maintenance worker what level they are on and what equipment they are near. This opens the capability to push the information to the mobile worker in the context of their current location. It is a much more proactive approach particularly suited to the small displays available on mobile devices such as tablets and smartphones.

Micro-geolocation can take a location and automatically provide the operator with diagnostic and/or procedural data. It also gives a view of real-time equipment status, maintenance information and manuals. In addition, micro-geolocation can provide the specific location and count of personnel in a given area and provide tracking/guidance for planned as well as unplanned events.

As smartphones and tablets become ubiquitous, users are accustomed to retrieving information as they move about. Equipped with GPS and wireless capabilities, and Internet-enabled, they allow LBS to drive content to these mobile devices.

Today, GPS will only work properly in a relatively unobstructed environment from the receiver to the satellites — otherwise there can be, at best, an intermittent signal. This is driving the market for indoor location technology. The next evolution of location-based apps will leverage indoor position-based service, which will enable location-based content while in areas where GPS is not available, such as indoors, in an outdoor location between tall structures or in industrial complexes.

Indoor location systems are forecasted to be the next-generation technology that will transform the location services industry market and enhance the mobile ecosystem. The world of the IoT, when fully realized, brings a next generation of connectedness seamlessly whether indoors or out. It will create the development of new and innovative services that will bridge the indoor/outdoor gap, deliver improved security and increased productivity, and further increase our dependence on our mobile devices, which will become the standard tools of our trade.

Proximity-based location benefits for efficiency

Indoor location technology was initially deployed as a way to target advertisements to consumers within retail outlets. By applying this technology to SCADA, access to relevant data within pumping stations and processing facilities will also benefit oil and gas operations. This leads to innovation in creating new location-contextual mobile SCADA and HMI applications as well as revolutionizing field service, analytics, logistics, optimization and a range of other related applications.

As these location-based services are deployed over the next few years, major improvements to operations and maintenance are expected. Minimally, we will see reduced downtime and improved reliability as maintenance workers are proactively provided live data and work processes based on their physical proximity to equipment. Operational efficiency will increase as the time taken to perform human-based tasks is reduced. Finally, and perhaps most importantly, safety improvements will be seen, as miscommunication risks are mitigated by proactively providing safety-critical information to the worker on their ever-present mobile device.

_80_80_c1.jpg)

Comments